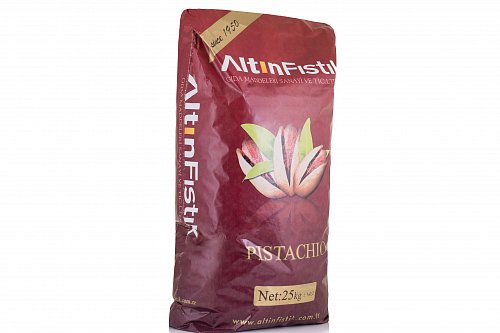

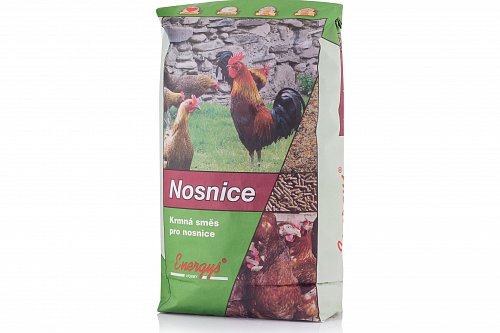

Valve Sacks

At present, the paper sack belongs among the most frequently used packaging for most loose materials.

This packaging gained its popularity mainly thanks to its excellent strength parameters, and its wide range of uses. Indisputably, the greatest advantage of the paper sack is the fact that it does not unnecessarily burden the environment, and protects consumers' wallets against high fees for the liquidation of packaging waste.

Thanks to the top quality and strength of the material used, two layers of paper are sufficient in the vast majority of cases – even for 50kg of product.